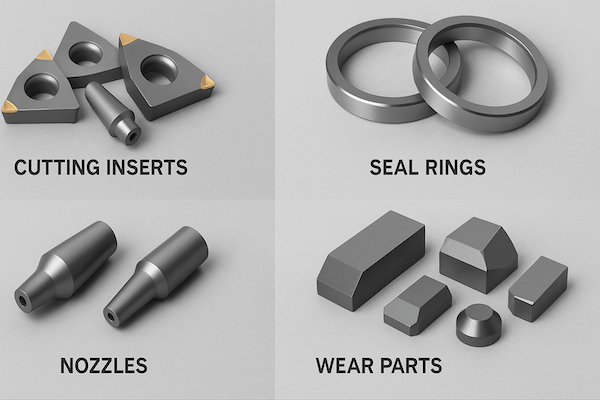

Tungsten Carbide Wear Parts

Dependable Tooling, Wear parts and Specialty Components

Partner with us for precision tungsten carbide parts: advanced equipment, ISO-certified quality, custom solutions, rapid global delivery, and 24/7 technical support to boost your productivity and success.

Wear parts and specialty components

Oil and natural gas wear parts

Tungsten carbide cutting tools

We have Sufficient Capabilities to Provide Better Services

As a leading tungsten carbide toolmaker, we offer advanced CNC tool grinders, diamond OD/ID grinders, and EDM machines—backed by expertly trained operators ensuring superior precision and reliability.

Grinding, machining and polishing

E.D.M.

We are the Top Tungsten Carbide Parts Manufacturer

As a leading tungsten carbide parts factory, we prioritize strict quality control at every production stage. Our expert team ensures that each product meets the highest standards, from material selection to final inspection, guaranteeing superior durability and precision.

With 14 years in the tungsten carbide parts industry, we have built a reputation for excellence. Our products are trusted in over 50 countries, demonstrating our capability to meet diverse customer needs and consistently deliver outstanding results worldwide.

We believe in providing exceptional service, offering personalized solutions and expert advice to every client. Our dedicated team works closely with customers to ensure timely deliveries, seamless communication, and satisfaction with every order.

RETOP

Talk to Us Now to Get a Quote?

High quality tungsten carbide parts helps for your industry

Tungsten carbide boosts durability and precision in woodworking, automotive, oil and natural gas, and more industries.

Woodworking

Oil and natural gas wear parts

Automotive

Tungsten Carbide FAQ

We want to provide you with the most helpful information, so you can make a self-educated purchase knowledge that will satisfied your specific needs

Glossary and technical lingo

Still have some questions?