57 Frequently Asked Questions (FAQs) about tungsten carbide

General Questions About Tungsten Carbide 1. What is tungsten carbide? Answer: Tungsten carbide is a hard, dense compound made from tungsten and carbon atoms. It is renowned for its exceptional hardness, wear resistance, and durability, making it ideal for various industrial applications. 2. How is tungsten carbide different from regular steel? Answer: Tungsten […]

Welcome to Retop Carbide

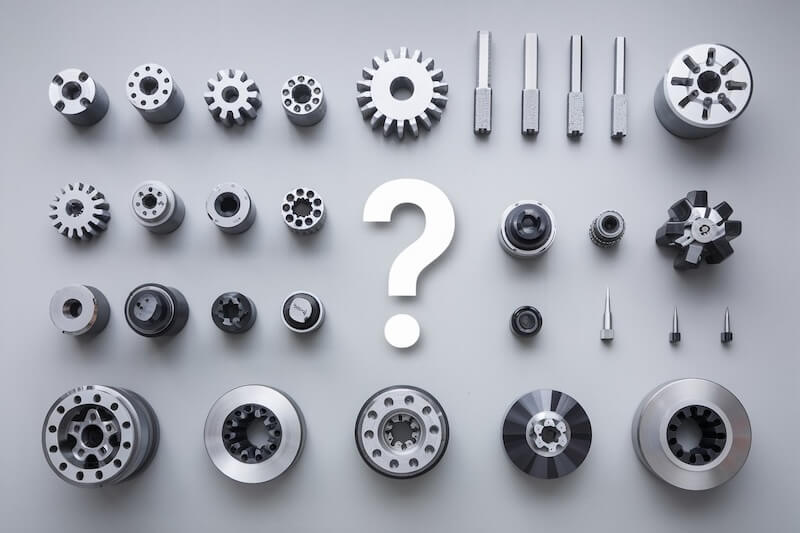

Welcome to Retop carbide, your partner for professional solutions in wear resistant industry. Welcome to Retop carbide, your partner for professional solutions in wear resistant industry. Our expertise in the engineering, production and finishing of sintered products comes from many years of experience start from 2010. We use our specialist manufacturing facilities to make these […]

Cost and Return on Investment (ROI): Maximizing Value with Tungsten Carbide Wear Parts

Introduction In the competitive landscape of modern manufacturing, the decision to invest in high-quality tooling is a strategic one that directly impacts a company’s operational efficiency, product quality, and profitability. Among the various materials available for wear parts tools, tungsten carbide stands out as a premium choice known for its exceptional hardness, wear resistance, and […]

Customization and Technical Support: Tailoring Solutions for Optimal Performance

Introduction In the competitive landscape of modern manufacturing, the ability to customize tooling solutions and receive comprehensive technical support is a significant determinant of success. Purchasers of tungsten carbide wear parts tools often seek not only high-quality, durable products but also tailored solutions that meet their specific operational needs. Additionally, robust technical support ensures that […]

Supplier Reliability and Reputation: Ensuring Trust and Consistency in Tungsten Carbide Wear Parts

Introduction In the competitive landscape of manufacturing, the reliability and reputation of a supplier are paramount factors that influence purchasing decisions. For companies investing in tungsten tungsten carbide wear parts tools, these considerations become even more critical due to the high-stakes nature of their applications. Tungsten carbide tools are integral to numerous manufacturing processes, requiring […]

How to check the quality and precision of tungsten carbide tools?

Introduction In the realm of manufacturing, the quality and precision of tools are paramount to ensuring the production of high-performance products. Tungsten carbide wear parts stand out as a superior choice for industries that demand exacting standards. This essay explores the importance of quality and precision in tungsten carbide tools and how factories can address […]