Chemical Stability in the Tungsten Carbide Industry: An Explanatory Overview

Introduction In the realm of advanced materials, chemical stability is a pivotal property that determines a material’s longevity, performance, and suitability for various industrial applications. In the tungsten carbide (WC) industry, chemical stability plays a crucial role in ensuring that components maintain their integrity and functionality under harsh chemical and environmental conditions. Tungsten carbide is […]

Metallography in the Tungsten Carbide Industry: An Explanatory Overview

Introduction In the high-performance world of materials science, metallography plays a pivotal role in understanding and optimizing the properties of metals and alloys. Specifically, in the tungsten carbide (WC) industry, metallography is essential for ensuring that products meet the stringent demands of various industrial applications. Tungsten carbide is renowned for its exceptional hardness, wear resistance, […]

Thermal Stability in the Tungsten Carbide Industry: An Explanatory Overview

Introduction In the realm of advanced materials, tungsten carbide (WC) stands out for its exceptional hardness, wear resistance, and high melting point. These properties make it indispensable in a variety of industries, including mining, aerospace, manufacturing, and automotive sectors. Among its numerous advantageous characteristics, thermal stability is a pivotal property that significantly influences the performance […]

Porosity in the Tungsten Carbide Industry: An Explanatory Overview

Introduction Porosity is a fundamental characteristic in the tungsten carbide (WC) industry, significantly influencing the material’s performance, durability, and suitability for various applications. Tungsten carbide, renowned for its exceptional hardness, wear resistance, and high melting point, is extensively used in industries such as mining, aerospace, manufacturing, and automotive. Understanding porosity—its causes, measurement, effects, and control—is […]

Understanding Grain Size in the Tungsten Carbide Industry

Introduction Grain size is a critical factor in determining the performance and quality of tungsten carbide (WC) tools and components. As one of the hardest and most wear-resistant materials, tungsten carbide is widely used in manufacturing industries for producing cutting tools, wear parts, and machinery components. The physical properties of tungsten carbide, including its hardness, […]

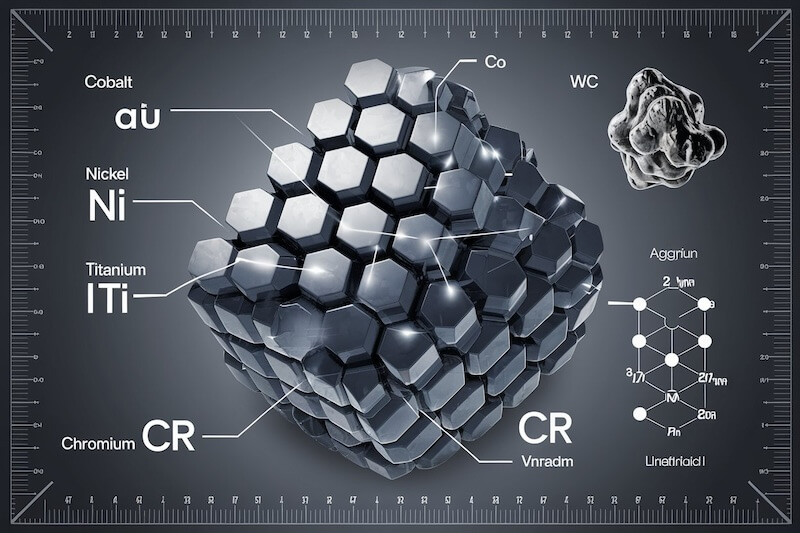

Understanding Alloying Elements in Tungsten Carbide: A Key Component of Industrial Excellence

Introduction In the world of materials science, the term alloying elements refers to elements that are deliberately added to a metal to enhance its properties, such as strength, hardness, corrosion resistance, and overall performance. In the tungsten carbide industry, the role of alloying elements is particularly important, as they directly influence the material’s hardness, wear […]