Introduction

Tungsten carbide (WC) is a unique and highly valuable material renowned for its hardness, wear resistance, and durability. These characteristics make tungsten carbide indispensable in a wide range of industries, including manufacturing, mining, and aerospace. While much attention is given to the material’s mechanical properties, its chemical properties also play a crucial role in determining its performance in various environments. In this article, we will explore the chemical properties of tungsten carbide, including its composition, resistance to corrosion and oxidation, and how it interacts with various chemicals. A deep understanding of these properties is essential for manufacturers and industries that rely on tungsten carbide components for long-lasting performance and durability.

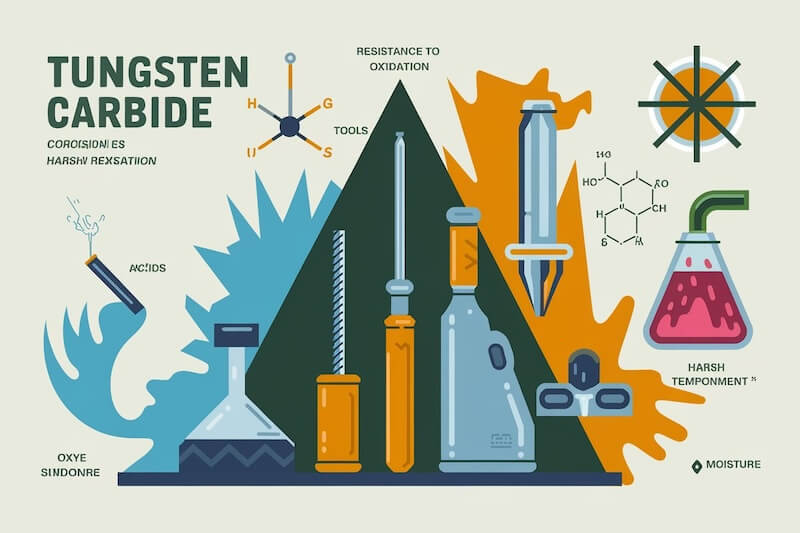

What are the Chemical Properties of Tungsten Carbide?

The chemical properties of tungsten carbide are integral to its behavior and longevity in different industrial applications. These properties include its elemental composition, resistance to corrosion, oxidation behavior, and its interaction with various chemicals. Let’s break these down:

Composition of Tungsten Carbide

Tungsten carbide is a compound made up of two primary elements: tungsten (W) and carbon (C). Tungsten is a transition metal, renowned for its high melting point (3422°C), and carbon is a non-metal element known for its ability to form strong covalent bonds with metals. When combined, these two elements form tungsten carbide, a ceramic-metal compound that boasts extraordinary hardness and wear resistance.

The typical chemical formula for tungsten carbide is WC, where each tungsten atom is bonded to a carbon atom. The tungsten carbide particles are bonded together using a metallic binder, usually cobalt (Co) or nickel (Ni). The binder not only holds the carbide grains together but also plays a role in the material’s toughness and corrosion resistance.

Resistance to Corrosion

One of the most important chemical properties of tungsten carbide is its corrosion resistance. Corrosion occurs when a material deteriorates due to chemical reactions with environmental elements, such as acids, salts, or water. Tungsten carbide, particularly when bonded with nickel, is highly resistant to many types of corrosion, including oxidation and chemical degradation.

The corrosion resistance of tungsten carbide is due to the strong bond between the tungsten and carbon atoms, as well as the hardness and inert nature of the material. Tungsten carbide’s resistance to wear and corrosion allows it to maintain its integrity even in aggressive chemical environments, making it a preferred choice in industries such as chemical processing, mining, and marine applications. However, the choice of binder material can affect corrosion resistance—cobalt, for instance, is more prone to corrosion than nickel, especially in acidic environments.

Oxidation Resistance

Oxidation refers to the reaction of a material with oxygen in the environment, which leads to the formation of oxides on the surface of the material. For many materials, oxidation leads to weakening and degradation over time. Tungsten carbide has an excellent resistance to oxidation, particularly at high temperatures. The strong covalent bonds between the tungsten and carbon atoms prevent the material from reacting with oxygen in the atmosphere, even at elevated temperatures.

At temperatures above 500°C, however, tungsten carbide can start to slowly oxidize, forming tungsten trioxide (WO₃) on the surface. This process is slower than the oxidation of many other metals, and in most industrial applications, tungsten carbide’s resistance to oxidation ensures its longevity and performance. To further enhance oxidation resistance, tungsten carbide can be treated with coatings or surface treatments, such as chromium or titanium, which form protective oxide layers that prevent oxidation.

Reaction to Acids and Bases

Tungsten carbide is highly resistant to many acids and bases, making it an ideal material for environments where exposure to these chemicals is common. For example, it can withstand acidic solutions like sulfuric acid and hydrochloric acid, which would corrode many metals. The material’s resistance to acidic environments makes it useful in applications such as chemical processing and the manufacture of acid-resistant components.

Similarly, tungsten carbide shows remarkable resistance to many basic (alkaline) solutions. The material is used in industries that deal with alkaline chemicals, including the production of machinery for handling slurries, caustic soda, and other basic solutions. However, exposure to certain extreme concentrations of acids or bases at elevated temperatures may lead to some degradation, particularly if the binder material (usually cobalt) reacts with the chemicals.

Interaction with Water and Moisture

Water and moisture are among the most common environmental factors that cause corrosion in metals and alloys. Tungsten carbide, however, exhibits high resistance to moisture and does not easily react with water. The material does not rust, a major advantage when it is used in humid environments or submerged in water. For example, tungsten carbide tools and parts used in mining and underwater operations can endure prolonged exposure to water without significant degradation.

That said, in very specific environments with high levels of chloride or other aggressive ions, there may be some impact on the material’s surface. Chloride ions, for example, can cause stress corrosion cracking in some metal alloys, including cobalt-bonded tungsten carbide. However, this is rare, and the material generally performs well in most aqueous environments.

Effect of High Temperatures on Chemical Properties

Tungsten carbide is often subjected to extreme temperatures in industrial applications. It is one of the few materials that can maintain its structural integrity and hardness at high temperatures, thanks to its high melting point and resistance to thermal expansion. However, at temperatures above 500°C, the interaction between tungsten carbide and oxygen begins, leading to oxidation.

In high-temperature environments, tungsten carbide’s binder material, usually cobalt or nickel, can become more reactive, which can affect the overall performance of the material. The temperature at which these reactions occur depends on the type of binder used and the specific environmental conditions. High-temperature applications, such as in turbines or cutting tools, require careful consideration of these chemical interactions, with nickel-bonded tungsten carbide being favored for its superior performance in elevated temperatures.

Applications of Tungsten Carbide

Based on its Chemical Properties

Tungsten carbide’s chemical properties make it an ideal material for a wide range of industrial applications where durability, resistance to corrosion, and high performance are essential. Some notable applications include:

Cutting Tools

Tungsten carbide is commonly used in cutting tools, including drills, end mills, and lathe tools. The material’s resistance to chemical degradation ensures that the tools maintain sharpness and precision even when cutting through materials like steel, titanium, and various alloys.

Mining Tools

Due to its hardness and resistance to abrasive conditions, tungsten carbide is used in mining tools, such as drill bits and rock crushers. The material’s corrosion resistance ensures that these tools can withstand the harsh chemical environments in which they operate, including exposure to water, chemicals, and high-pressure conditions.

Chemical Processing Equipment

In industries such as chemical manufacturing, tungsten carbide is used for components like valves, pumps, and nozzles. Its ability to withstand acidic and basic chemicals makes it indispensable in environments where these substances are handled.

Aerospace and Automotive Components

Tungsten carbide’s high resistance to oxidation and wear at elevated temperatures makes it useful in aerospace and automotive industries. It is employed in components like turbine blades, valves, and high-performance bearings.

Conclusion

The chemical properties of tungsten carbide are fundamental to its performance in various industrial applications. Its resistance to corrosion, oxidation, acids, bases, and moisture, as well as its high-temperature stability, make it a versatile and durable material. Understanding these chemical properties is essential for selecting the right tungsten carbide for specific applications and ensuring its long-term performance. As industries continue to evolve and require higher performance materials, tungsten carbide will remain a critical material due to its robust chemical and mechanical properties.