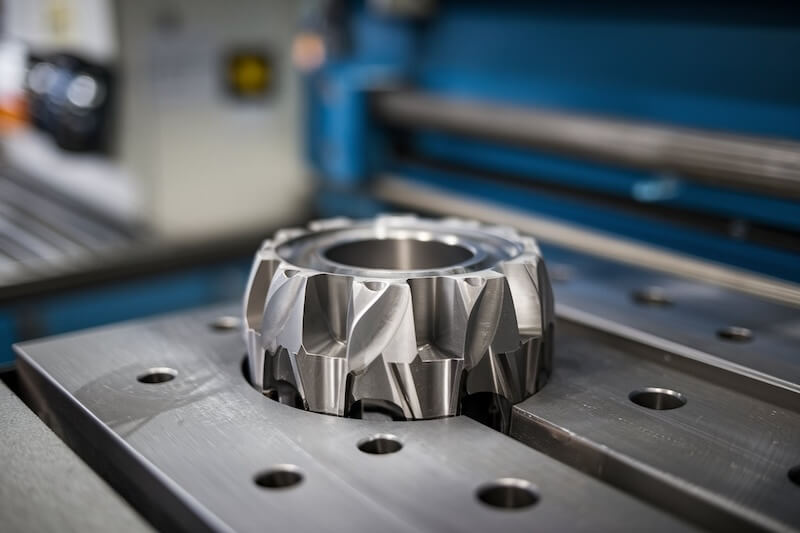

Tungsten Carbide Can Tooling

Retop Carbide designed to highlight the value that tungsten carbide tooling brings to the can manufacturing industry. We share with both machine operators, who understand the day-to-day production challenges, and decision-makers, who seek strategic investments that enhance competitiveness and profitability. By showcasing the benefits of tungsten carbide tools—especially those offered by Retop— aims to demonstrate how upgrading tooling can result in better quality, improved efficiency, and long-term growth.

Quick and easy: Enter your specifications and get a quote in one business day

Table of Contents

Expertise in Tungsten Carbide Can Tooling

Trust Retop Carbide to manufacture your can tooling. We manufacture high-quality 2-Piece Can Tooling, 3-Piece Can Tooling, Tungsten Carbide Can Tooling, Tool Steel or Ceramic Can Tooling, and other carbide can components and tooling for cans to outperform their work requirements.

Types of Can Tooling

- 3 Piece Can Making Mold

- 2 Piece Can Making

- Cut-Edge Rings

- Carbide Can Tooling Draw Dies and Rings

- Forming Punches

- Shell Punches

- Extrusion Dies

- Curling Punches

- Punch Shells

- Inner Punch Rings

- Draw Rings

- Draw Pads

- One-Piece Extrusion Dies

- Cupping Draw Dies

- Ceramic Rollers

- Spin Curl Rollers

- Trimming Dies

- Die Center Rings

- Inner Cut-Edge Rings

- Die Center Buttons

- Punch Caps

- Cupper Tooling

- Body Maker Punches

- Can Neck Tooling

- Can Punch Sleeves

- Can Cupper Press

- Can Bodymaker

- Carbide-Lined Dies

- Blank Cut Edges

- Shim Plates

- Custom Tooling for Cans

- Custom Ceramic Tooling

Introduction: Rising Standards in Can Manufacturing

In a global marketplace where brands compete on both quality and cost, can manufacturers must continuously refine their processes. Achieving consistent wall thicknesses, seamless finishes, and minimal waste is crucial. Tungsten carbide tooling provides the precision, durability, and reliability necessary to meet these high standards.

Details:

- Complex Requirements: From beverage cans to aerosol containers, achieving uniform thickness and exact dimensions is essential.

- Consumer Expectations: Modern customers demand visually flawless cans and lightweight designs, pushing manufacturers to invest in superior tooling solutions.

The Superior Properties of Tungsten Carbide

Tungsten carbide stands out for its exceptional hardness, resistance to wear, and overall toughness, making it a prime choice for demanding manufacturing environments.

Details:

- Enhanced Hardness: Tungsten carbide is significantly harder than traditional tool steels, ensuring cutting edges remain sharp through extended production runs.

- Wear Resistance: Tools made from tungsten carbide show minimal degradation even under continuous, high-speed operations.

- Dimensional Stability: Consistent tool geometry reduces setup changes and allows operators to maintain tighter tolerances on can dimensions.

Increasing Productivity and Throughput

By reducing tool changes, minimizing maintenance time, and enabling faster cutting or forming speeds, tungsten carbide tools elevate overall productivity.

Fewer Tool Replacements

Longer tool life means less downtime spent swapping dull or damaged tools.

Higher Output

Stable, predictable cutting performance allows for increased line speeds without compromising accuracy.

Optimized Workflow

With reliable tools, operators can focus on fine-tuning processes and achieving optimal production flow, rather than constantly adjusting tooling parameters.

Quick and easy: Enter your specifications and get a quote in one business day

Enhancing Surface Finish and Consistency

Smooth surfaces and uniform thickness are critical for can quality, influencing both the appearance and functionality of the final product. Tungsten carbide tools excel at delivering superior surface finishes.

Details:

- Reduced Friction: Consistent cutting edges reduce friction and wear on the can material, producing smoother surfaces.

- Improved Coating Adhesion: For cans that require protective coatings or decorative prints, a high-quality surface finish improves adhesion and visual appeal.

- Less Scrap and Rework: Fewer imperfections mean lower scrap rates, cutting material costs and enhancing profit margins.

Cost Savings Over the Tool Lifecycle

While tungsten carbide tools may require a higher initial investment, their extended service life and reliable performance generate significant long-term cost savings.

Details:

- Longer Tool Life: Lasting far longer than conventional tooling, tungsten carbide reduces the frequency and cost of replacements.

- Maintenance Efficiency: Lower wear rates cut down on maintenance labor, spare part inventories, and emergency downtime.

- Better Return on Investment: Over time, improved productivity, less waste, and fewer outages offset the initial expenditure, leading to substantial net gains.

Durability in Challenging Production Environments

Can manufacturing often involves rapid cycles, continuous operations, and abrasive materials. Tungsten carbide’s resilience allows it to thrive in these demanding conditions.

Details:

- Resistance to Heat and Corrosion: Tungsten carbide retains its properties under high-speed, high-temperature conditions common in can forming.

- Adaptable to Material Variations: Whether working with standard aluminum or specialty alloys, tungsten carbide tools maintain consistent performance.

- Stable Performance Under Pressure: Operators benefit from tools that remain reliable even during intensive production runs or sudden shifts in material batches.

Partnering with Retop: Expertise and Tailored Solutions

Retop’s deep industry knowledge, technical support, and customization options ensure can manufacturers get the best possible results from tungsten carbide tooling.

Details:

- Engineering Support: Retop’s experts help identify the ideal tungsten carbide grade, tool geometry, and finishing techniques for specific can lines.

- Custom Tool Design: Whether a company is producing standard beverage cans or specialized containers, Retop can tailor tools to unique specifications.

- After-Sales Service: Ongoing consultation, prompt delivery of replacements, and continuous process optimization support sustain high-performance operations.

Future-Proofing Your Can Manufacturing Process

As market trends evolve, adopting tungsten carbide tools prepares can manufacturers to adapt quickly and meet emerging challenges.

Details:

- Scaling for Growth: Superior tooling supports higher production volumes, enabling companies to expand their markets with confidence.

- Innovation-Ready: Tungsten carbide tooling remains effective as new materials, coatings, and container designs emerge.

- Competitive Advantage: By investing in advanced tooling now, companies can maintain a leading edge, attracting and retaining clients who demand top-notch packaging.

Conclusion

From tighter tolerances and enhanced finishes to cost savings and sustainable growth, tungsten carbide tooling represents a strategic upgrade for the can manufacturing industry.

For decision-makers assessing ways to boost productivity and quality, and for machine operators seeking stable, high-performance tools, tungsten carbide offers a clear path to improvement.

Partnering with Retop ensures not just the acquisition of premium tungsten carbide tools, but also the technical guidance and support needed to make the most of that investment.

As the can manufacturing industry moves forward, tungsten carbide tooling stands as a key factor in achieving operational excellence and meeting consumer demands.

Quick and easy: Enter your specifications and get a quote in one business day