Tungsten Carbide Recycling

Retop Carbide helps companies and individuals understand why sending their unused tungsten carbide to a professional manufacturer for recycling is a responsible and beneficial choice. By understanding the environmental consequences and the value of proper recycling, they can make an informed decision that supports both their interests and the health of our planet.

Quick and easy: Enter your specifications and get a quote in one business day

Table of Contents

Types of Tungsten Carbide Recycling

Retop Carbide makes tungsten carbide recycling easy.

Understanding Tungsten Carbide and Its Composition

Tungsten carbide is a composite material known for its hardness, durability, and wear resistance, which makes it a staple in cutting tools, mining equipment, and industrial machinery.

Details:

- Material Structure: Tungsten carbide blends tungsten, carbon, and a metal binder like cobalt, forming a material harder than most steels.

- Widespread Use: Found in drills, saw blades, and various industrial tools, tungsten carbide has become ubiquitous across many sectors.

- Lifespan and Waste: Eventually, when tools or parts wear out, they may be discarded, leading to the accumulation of tungsten carbide waste.

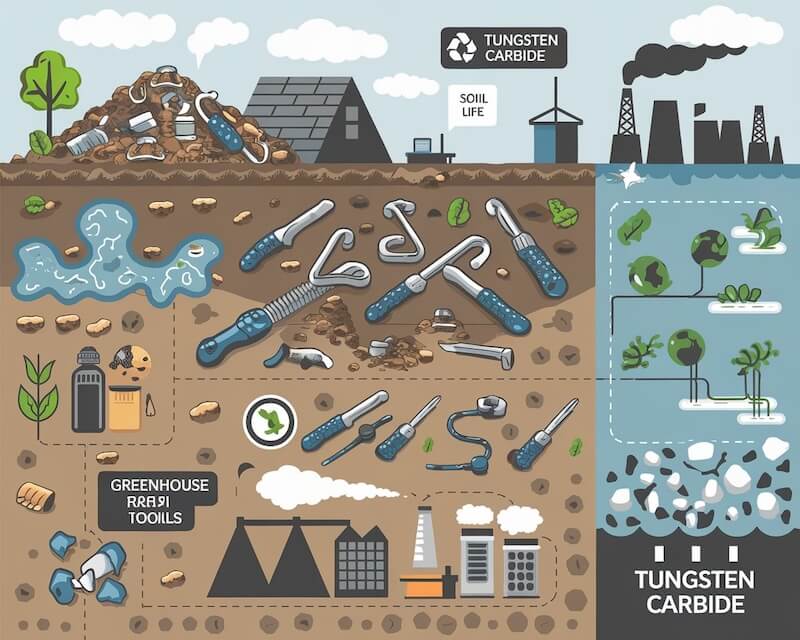

The Environmental Impact of Improper Disposal

Discarding tungsten carbide into landfills or neglecting proper disposal can harm the environment.

Details:

- Resource Depletion: Tungsten is a finite resource; throwing it away wastes valuable materials that could be reused.

- Soil and Water Contamination: Improperly discarded tungsten carbide may leach binders or other elements that affect local ecosystems.

- Greenhouse Gas Emissions: Manufacturing tungsten carbide from raw materials consumes energy, so not recycling increases the carbon footprint associated with producing new material.

Why Recycling Matters for the Earth’s Health

Recycling tungsten carbide reduces environmental damage, conserves resources, and lessens the industry’s ecological impact.

Conservation of Raw Materials

Recycling recovers tungsten and other components, reducing the need for new mining activities and preserving natural resources.

Energy Savings

Reprocessing existing tungsten carbide often requires less energy than producing fresh material from ores, lowering greenhouse gas emissions.

Ecosystem Protection

By keeping tungsten carbide out of landfills, we minimize the risk of soil and water pollution.

Quick and easy: Enter your specifications and get a quote in one business day

The Role of Professional Tungsten Carbide Manufacturers in Recycling

Experienced tungsten carbide manufacturers possess the specialized knowledge and equipment needed to safely and efficiently recycle unused materials.

Details:

- Advanced Technology: Professional facilities use state-of-the-art methods like chemical recycling and mechanical processing to recover tungsten and cobalt.

- Quality Assurance: Expert oversight ensures that recycled tungsten carbide retains its structural integrity and hardness, suitable for future industrial uses.

- Regulatory Compliance: Reputable manufacturers adhere to environmental regulations, ensuring that recycling practices are safe and legally compliant.

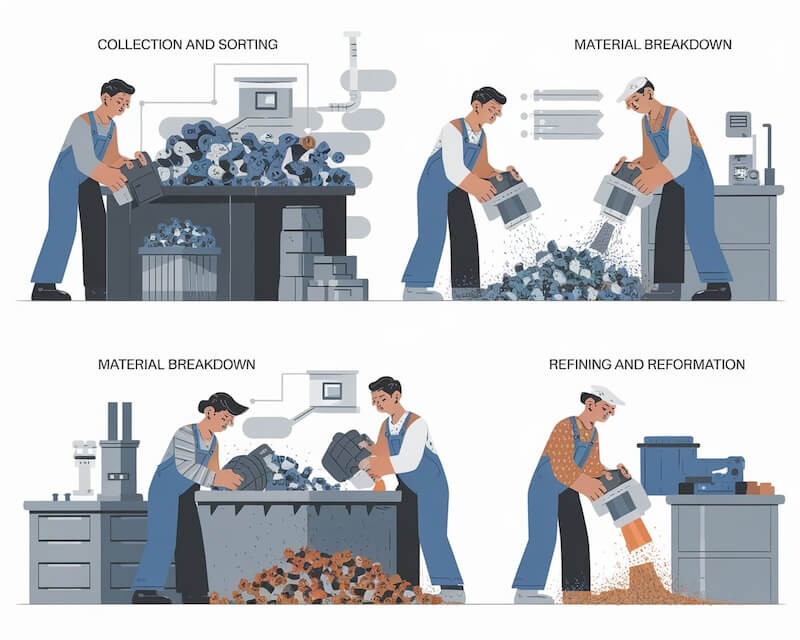

The Process of Recycling Tungsten Carbide

Recycling involves several critical steps, from collecting waste to reintroducing high-quality material back into the market.

Details:

- Collection and Sorting: Companies and individuals gather and deliver used tungsten carbide tools to recycling facilities.

- Material Breakdown: The material undergoes crushing, grinding, and chemical treatments to separate tungsten from binders and impurities.

- Refining and Reformation: Recovered tungsten powder is re-sintered into new tungsten carbide products, ensuring a sustainable, closed-loop production cycle.

Business Benefits of Recycling for Companies

Beyond environmental responsibility, recycling offers tangible advantages for businesses.

Details:

- Cost Savings: Selling scrap tungsten carbide back to recyclers or reusing recycled material can reduce expenses associated with raw material procurement.

- Brand Image: Demonstrating a commitment to sustainable practices enhances a company’s reputation, appealing to environmentally conscious customers and stakeholders.

- Competitive Edge: With increasingly strict environmental regulations, adopting recycling practices positions a company as forward-thinking and compliant.

Encouraging Individuals and Smaller Workshops to Participate

Even if you’re not a large enterprise, sending tungsten carbide to professional recyclers is easy, beneficial, and accessible.

Details:

- Educational Resources: Manufacturers provide guidance on how to identify and package tungsten carbide waste for safe shipping.

- Simple Logistics: Many recyclers offer pick-up services, drop-off locations, or pre-paid shipping options for small quantities.

- Collective Impact: By contributing even small amounts of tungsten carbide, individuals help reduce environmental harm and support a culture of sustainability.

How to Get Started with Our Tungsten Carbide Recycling Services

Taking action is straightforward and can begin immediately.

Details:

- Contacting Our Team: Reach out to our recycling department to discuss your tungsten carbide waste quantity, condition, and scheduling.

- Assessment and Quotation: Our experts will evaluate the material and provide guidance on best practices, pricing, and timelines for recycling.

- Long-Term Partnerships: We encourage ongoing relationships, helping you set up regular recycling programs, ensuring steady material recovery and environmental benefits.

Conclusion

Tungsten carbide is an indispensable material with extraordinary properties, but it also requires careful handling once it has served its purpose.

By understanding the environmental impact of improper disposal and recognizing the value of recycling, companies and individuals can make choices that benefit both their bottom line and the planet.

Partnering with professional tungsten carbide recyclers ensures that unused material is effectively reclaimed, reducing environmental harm and creating a more sustainable future for all.

Quick and easy: Enter your specifications and get a quote in one business day