Carbide Burrs for Metal Grinding

- Product Name: Carbide burrs for metal grinding

- Material: Hard alloy, cemented carbide, tungsten steel

- Density: 14.5-14.8 g/cm3

- Hardness: HRA89-90

- Type: Single cut, double cut, Aluminum cut

- Features: Long service life, high accuracy, great efficiency

Description:

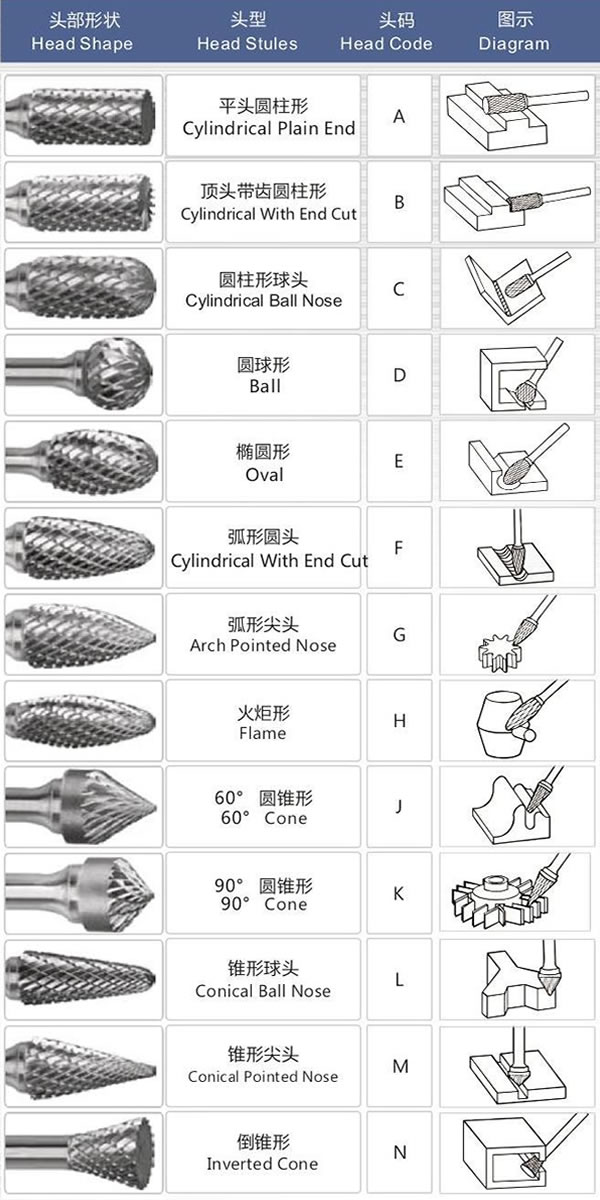

1. Various type of head shapes, cutting styles and sizes are available for wide range of applications.

2. Ideal for metalworking applications such as machining and deburring.

Specifications:

| Name: | Tungsten carbide burrs |

| Other names: | tungsten rotary burrs, tungsten metal burrs, cemented rotary burrs |

| Features | long working life, high stock removal, ideal for using on many tough materials. Ideal for finishing, carving, shaping and deburring welds, moulds, dies and forgings. |

| For drilling holes in hard metals | carbide micro drills, or carbide straight shank drills |

| For cutting slots, routing, profiling, | carbide end mill, carbide router, or slot drill |

| For cutting stone or glass | Diamond Burr |

Versatility is a key feature of our tungsten carbide burrs. They are highly effective on a wide range of materials, including aluminum, cast iron, copper, zinc alloys, wood, and steel, among others. Whether you’re deburring, shaping, grinding, or removing material, our burrs offer exceptional performance and reliable results across various industries, including metalworking, woodworking, automotive, and more.

Ease of use and compatibility are paramount considerations. Our burrs are designed to seamlessly integrate with rotary tools such as die grinders or electric drills. The precisely engineered shanks ensure secure and stable attachment, enabling you to work with confidence and precision.

Each burr undergoes stringent quality control measures to ensure that it meets the highest standards of performance and durability. Our commitment to excellence ensures that you receive a cutting tool that exceeds your expectations and enhances your productivity.

|  |  |