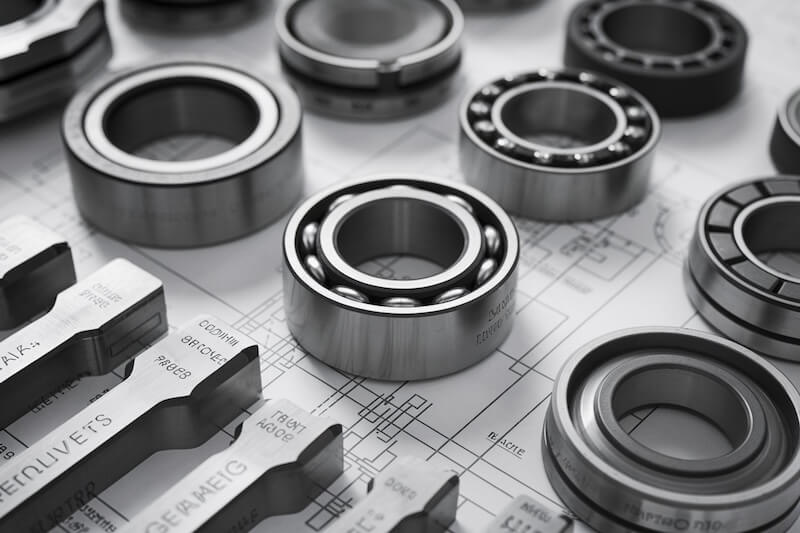

Ball Bearing Manufacturing Carbide Tooling

Retop highlighting how tungsten carbide tooling can revolutionize ball bearing manufacturing. It’s designed for both machine operators, who engage with tooling daily, and decision-makers aiming to enhance their company’s competitiveness. The goal is to illustrate how tungsten carbide tools—particularly those from Retop—deliver tangible benefits that justify the investment.

Quick and easy: Enter your specifications and get a quote in one business day

Table of Contents

Expertise in Ball Bearing Manufacturing Carbide Tooling

Retop Carbide manufactures Ball Bearing Die Sets, Ball Bearing Wear Parts and other Ball Bearing specialty components and tooling customized to your specifications.

Types of Ball Bearing Tooling

- Roller Bearing Tooling

- Ball Bearing Punch Die Tooling

- Ball Bearing Wear Parts

- Ball Bearing Specialty Tooling

- Ball Bearing Die Sets

- Ball Bearing Components

Meeting the High-Precision Demands of Ball Bearing Manufacturing

Ball bearings require exceptional dimensional accuracy and smooth finishes to ensure reliable performance, reduced friction, and prolonged service life. Tungsten carbide tools excel at delivering this precision.

Details:

- Tight Tolerances: Tungsten carbide’s inherent hardness and rigidity enable tools to maintain their shape, achieving the exacting tolerances required in ball bearing races and rolling elements.

- Consistent Quality: By using tungsten carbide tooling, operators achieve uniform results from one batch to the next, reducing variability and enhancing overall product reliability.

Enhanced Tool Life and Reduced Downtime

Longer-lasting tools contribute to greater manufacturing efficiency, fewer stoppages, and better use of resources. Tungsten carbide’s durability extends tool life significantly.

Details:

- Wear Resistance: Tungsten carbide’s superior hardness ensures that cutting edges and forming tools stay sharp longer, minimizing frequent tool changes.

- Lower Maintenance Costs: Less time spent swapping out worn tools and reconditioning dull edges means less downtime, streamlined operations, and reduced maintenance expenses.

Improving Operational Efficiency and Throughput

High-quality tungsten carbide tooling increases production speed without compromising accuracy, allowing manufacturers to meet volume targets and maintain quality.

Consistent Cutting Performance

Tungsten carbide tools maintain stable cutting forces, enabling higher cutting speeds and feeds, ultimately improving production rates.

Predictable Tool Behavior

When operators trust their tools to perform consistently, they can fine-tune cycle times and optimize throughput, meeting tight delivery schedules more easily.

Quick and easy: Enter your specifications and get a quote in one business day

Superior Surface Finishes for Enhanced Bearing Performance

Surface finish quality directly influences bearing friction, noise reduction, and overall performance. Tungsten carbide tools produce exceptionally smooth and polished surfaces.

Details:

- Reduced Friction and Heat: Smooth raceway surfaces minimize friction and wear between bearing components, enhancing energy efficiency and extending bearing life.

- Improved End-User Satisfaction: High-precision bearings with superior finishes contribute to quieter, more efficient machinery, satisfying end-users and strengthening brand reputation.

Increased Product Reliability and Reduced Defect Rates

High-precision tooling lowers the incidence of manufacturing defects, leading to improved batch consistency and fewer rejected parts. Tungsten carbide’s stability is key.

Details:

- Dimensional Stability: Tungsten carbide tools maintain form under high pressures and temperatures, preserving part accuracy and reducing scrap rates.

- Higher Yield: Fewer defective bearings mean better material utilization, less waste, and improved cost-effectiveness—all critical for long-term profitability.

Suitability for Diverse Bearing Materials and Designs

The ball bearing industry is increasingly experimenting with various steels and coatings. Tungsten carbide’s adaptability ensures optimal results across a range of materials and bearing designs.

Details:

- Versatile Application: From standard carbon steel bearings to specialty alloys or ceramic-coated components, tungsten carbide tooling can handle a broad spectrum of materials.

- Future-Proofing Production: As bearing designs evolve, tungsten carbide’s robust performance capabilities ensure manufacturers can quickly adjust processes without sacrificing quality.

Sustainable Manufacturing and Resource Efficiency

Longer-lasting, high-performance tools like those made from tungsten carbide support sustainability and resource efficiency—key corporate priorities in modern manufacturing.

Details:

- Reduced Resource Consumption: Tools that last longer reduce the frequency of replacements, decreasing material waste and lowering environmental impact.

- Energy Efficiency: Stable, efficient cutting processes enabled by tungsten carbide can also reduce energy consumption on the production line, contributing to greener manufacturing operations.

Partnering with Retop for Specialized Tungsten Carbide Solutions

Retop’s experience, technical support, and custom solutions ensure that ball bearing manufacturers gain the most from their investment in tungsten carbide tooling.

Details:

- Tailored Tooling Solutions: Retop’s engineering team collaborates closely with clients to select the right tungsten carbide grade, geometry, and coating for each bearing component.

- Reliable Support and Service: Ongoing technical guidance, prompt customer service, and proactive tool management solutions help companies optimize their entire production process and stay ahead of market demands.

Conclusion

Tungsten carbide tooling represents a strategic investment for ball bearing manufacturers who seek improved efficiency, higher product quality, and long-term cost savings.

From reducing downtime and scrap rates to delivering precision and versatility, tungsten carbide tools provide a clear competitive edge.

By partnering with Retop, decision-makers ensure they’re working with a trusted provider that understands their needs, offering comprehensive solutions that elevate operational excellence and strengthen their market position.

Quick and easy: Enter your specifications and get a quote in one business day