Battery Carbide Tooling

Retop demonstrating how tungsten carbide tools support battery manufacturing. The intended audience includes both machine operators, who value practical improvements in day-to-day operations, and CEOs, who seek strategic investments to enhance quality, efficiency, and brand reputation. By highlighting the benefits of tungsten carbide tools—particularly those offered by Retop—this article aims to illustrate their indispensable role in the growing and increasingly competitive battery industry.

Quick and easy: Enter your specifications and get a quote in one business day

Table of Contents

Expertise in Battery Carbide Tooling

Retop Carbide’ specialty alkaline battery tooling is trusted and used by the manufacturing leaders in the industry.

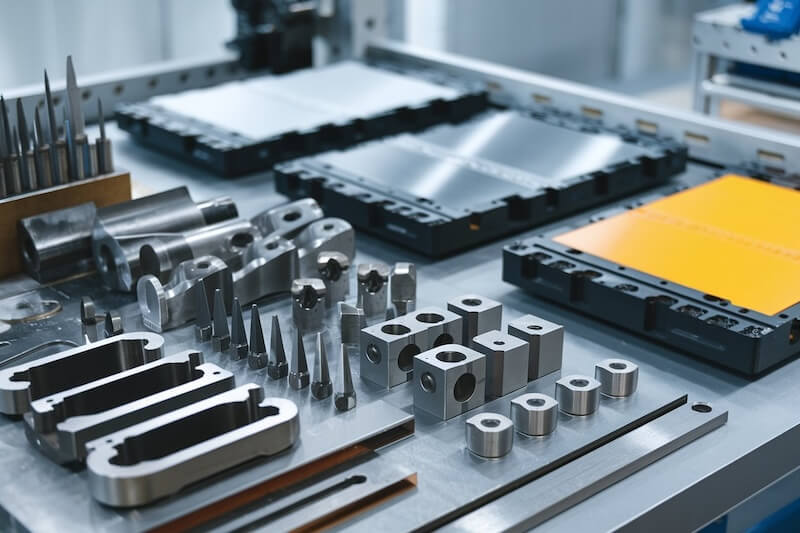

Types of Battery Tooling

- Carbide Punches and Dies

- Cut-Edge Rings

- Draw Dies

- Forming Punches

- Trimming Dies

- Stamping Dies

- Core Rods

- Carbide Wire Guides

- Other

Introduction: Meeting the Rising Demands of Battery Manufacturing

As the global demand for batteries increases—driven by electric vehicles, energy storage solutions, and portable electronics—battery manufacturers face mounting pressure to boost efficiency, quality, and scalability.

Details:

- Stringent Requirements: Today’s batteries must be produced with high precision to ensure safety, reliability, and consistent performance.

- Material Challenges: Delicate components like electrode sheets and casings demand tooling solutions that maintain their integrity and accuracy over prolonged production runs.

- Competitive Landscape: Achieving these goals often means investing in superior tooling that supports higher production volumes and better end-product quality.

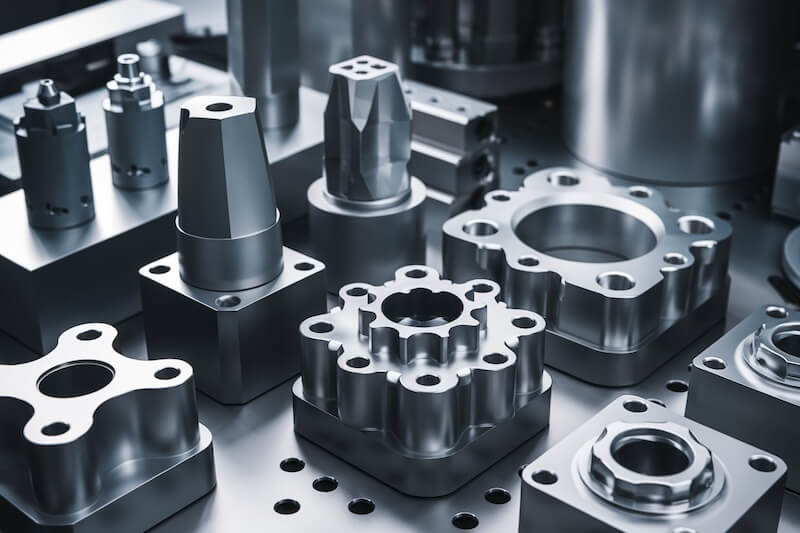

The Unique Properties of Tungsten Carbide

Tungsten carbide stands out for its exceptional hardness, wear resistance, and thermal stability—properties that are crucial in battery manufacturing environments.

Details:

- Hardness and Durability: Tungsten carbide tools maintain their sharpness and shape longer than traditional steel tools, enduring the rigors of cutting, shaping, and drilling battery components.

- Thermal Stability: Even under the friction and heat generated by high-speed processes, tungsten carbide retains its structural integrity, ensuring consistent machining quality.

- Wear Resistance: Lower wear rates mean fewer tool changes, more stable production lines, and a steady output of quality parts, ultimately improving operational efficiency.

Enhanced Production Efficiency and Throughput

Tungsten carbide tools can significantly reduce downtime and maintenance, enabling faster production cycles and improved throughput.

Extended Tool Life

Longer-lasting tools mean reduced frequency of tool changes, minimizing line stoppages and increasing overall production capacity.

Consistent Machining Quality

Machine operators can rely on uniform cutting performance, resulting in fewer adjustments, quicker setups, and shorter lead times.

Optimized Workflow

An efficient production line supported by robust tooling fosters a lean manufacturing environment where every second counts toward higher output and profitability.

Quick and easy: Enter your specifications and get a quote in one business day

Superior Quality Control and Product Reliability

With tungsten carbide tooling, battery manufacturing achieves high precision, resulting in tighter tolerances and better component consistency.

Details:

- Consistent Part Geometry: Accurate, repeatable cuts and shapes reduce defects in battery components, enhancing product reliability and overall battery performance.

- Improved Surface Finishes: Smooth, precise surfaces improve electrode integrity and reduce the likelihood of contamination or performance degradation within the battery.

- Reduced Scrap Rates: Higher-quality tooling diminishes the incidence of misaligned or flawed parts, lowering material waste and improving cost efficiency.

Durability in Demanding Manufacturing Environments

Tungsten carbide tools withstand harsh conditions commonly found in battery production, enabling stable operations in challenging scenarios.

Details:

- High-Volume Production: Continuous runs and extended shifts put heavy stress on tools, making tungsten carbide’s resilience a critical advantage.

- Complex Components: From electrode slitting to battery casing formation, tungsten carbide tools maintain accuracy, even with intricate shapes and demanding materials.

- Minimized Downtime: Greater reliability ensures less downtime due to tool failure or frequent replacements, improving overall equipment effectiveness (OEE).

Sustainability and Resource Efficiency

Tungsten carbide tooling supports sustainable manufacturing initiatives by reducing waste, energy consumption, and the environmental footprint of battery production.

Details:

- Lower Material Waste: Consistent cutting accuracy leads to fewer rejected parts and less raw material consumption.

- Energy Efficiency: Stable, predictable machining operations help control energy usage, cutting operating costs and aligning with corporate sustainability goals.

- Longevity and Reusability: Tungsten carbide tools have the potential to be reconditioned or recycled, further enhancing the environmental and economic benefits over their lifecycle.

Partnering with Retop for Customized Solutions

Retop offers specialized tungsten carbide tools tailored to the unique needs of battery manufacturers, providing expert guidance and dependable service.

Details:

- Industry Expertise: Retop’s in-depth knowledge of tungsten carbide grades, tool geometries, and finishing processes ensures optimized solutions for every application.

- Collaborative Approach: Working closely with customers, Retop fine-tunes tooling designs to achieve the perfect balance of precision, durability, and cost-effectiveness.

- After-Sales Support: Responsive technical support, maintenance advice, and ongoing consultation help customers get the most out of their tungsten carbide investments.

Future-Proofing Your Battery Manufacturing Operations

As battery technology evolves, investing in tungsten carbide tools prepares companies to meet emerging challenges and seize new opportunities.

Details:

- Advanced Materials Compatibility: Tungsten carbide tooling adapts easily to new materials and processes in next-generation batteries, ensuring a seamless transition to future requirements.

- Market Leadership: Adopting high-performance tooling positions manufacturers as industry leaders, ready to deliver cutting-edge products with greater speed and precision.

- Sustained Growth: Strengthening your production capabilities now sets the stage for long-term success, customer loyalty, and a stable market position.

Conclusion

From enhanced efficiency and quality to sustainability and future readiness, tungsten carbide tooling represents a strategic investment for battery manufacturers.

For CEOs aiming to maximize competitiveness and profitability, and for machine operators seeking better day-to-day reliability, tungsten carbide tools—especially those from Retop—offer tangible advantages.

By embracing these solutions, manufacturers elevate their production standards, confidently meet industry demands, and pave the way for continued innovation and success in the rapidly growing battery market.

Quick and easy: Enter your specifications and get a quote in one business day