Carbide Tools in Housing

Retop carbide designed to provide a clear, structured understanding of why tungsten carbide stands out as the best choice for housing cutting tools. It addresses both manufacturing decision-makers and tool users who are currently unsure about the switch to tungsten carbide. By highlighting the material’s core properties, operational advantages, and long-term benefits, this article aims to convince you that investing in carbide tooling is a strategic move that can elevate your production quality and efficiency.

Quick and easy: Enter your specifications and get a quote in one business day

Table of Contents

Expertise in Carbide Tools in Housing

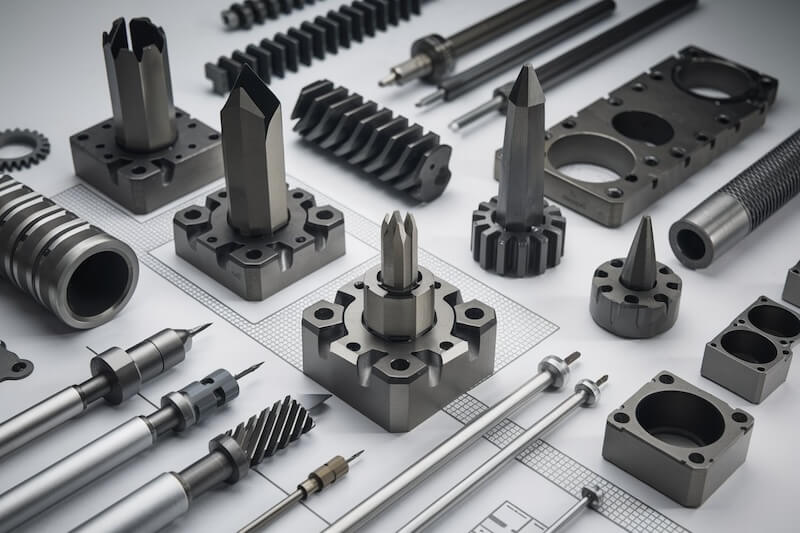

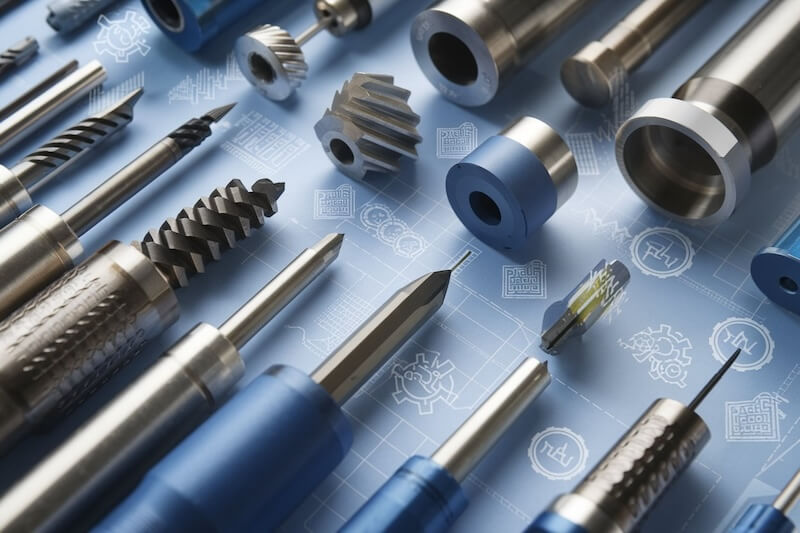

Retop Carbide produces a wide range of blanks for the housing industry, including roofing dies, tile cutters, and brick mold tooling.

Types of Carbide Tools in Housing

- Roofing Dies

- Tile Cutters

- Brick Mold Tooling

- Tungsten Carbide Preforms for Construction Tooling

- Tungsten Carbide Blanks for Construction Tooling

Introduction: The Growing Need for Advanced Housing Cutting Tools

As demands on machining precision and productivity rise, traditional tool materials can struggle to keep up. Tungsten carbide offers a more robust solution perfectly aligned with the evolving challenges of housing manufacturing.

Details:

- Higher Industry Standards: Complex housing designs and tighter tolerances demand tooling that can maintain exacting quality in high-volume scenarios.

- Global Competition: To stand out in a crowded marketplace, tools that deliver faster cycles and fewer defects are no longer optional—they are essential.

Fundamental Properties of Tungsten Carbide

Tungsten carbide’s unique metallurgical makeup endows it with significant advantages over conventional tool steels.

Details:

- Exceptional Hardness: Tungsten carbide is significantly harder than standard HSS (High-Speed Steel), ensuring cutting edges stay sharper for longer.

- Increased Wear Resistance: Its dense, wear-resistant microstructure substantially reduces tool degradation over extended runs.

- Dimensional Stability: Carbide tools maintain their geometry and cutting integrity under stress and temperature fluctuations.

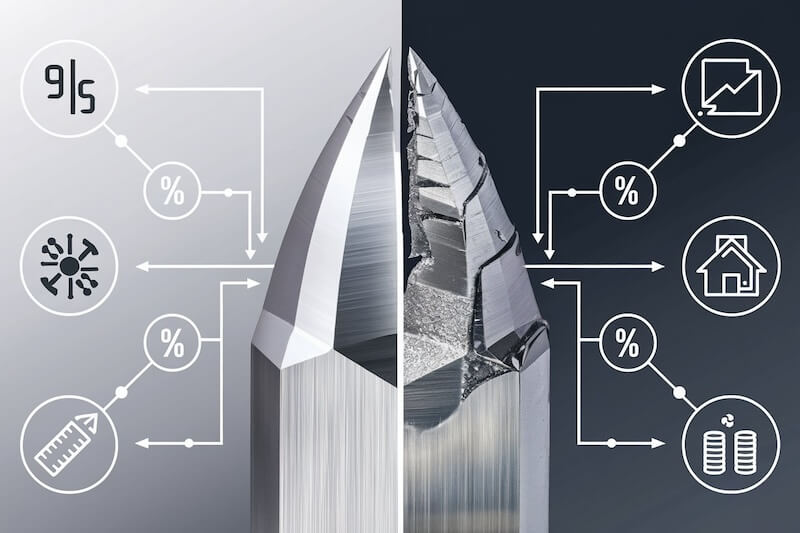

Performance Comparison: Carbide vs. Other Materials

A direct comparison highlights where tungsten carbide truly excels, making it the material of choice for housing cutting tools.

Carbide vs. HSS

While HSS tools are cheaper upfront, they dull faster and require frequent replacements, leading to higher long-term costs.

Carbide vs. Ceramics

Ceramics can be brittle, leading to chip-outs or premature tool failure, whereas carbide offers a balance of toughness and hardness.

Carbide vs. Coated Steels

Even coated steels struggle to match carbide’s consistent performance once coating layers wear away.

Quick and easy: Enter your specifications and get a quote in one business day

Enhanced Machining Efficiency and Cycle Times

Faster machining speeds and better tool life directly translate into improved operational efficiency. Tungsten carbide excels in these respects.

Details:

- Higher Cutting Speeds: Carbide’s hardness allows for more aggressive feeds and speeds without compromising tool integrity.

- Reduced Downtime: Extended tool life means fewer changeovers, less re-sharpening, and more productive machine utilization.

- Consistent Output: Stable performance leads to predictable cycle times and smoother workflow management.

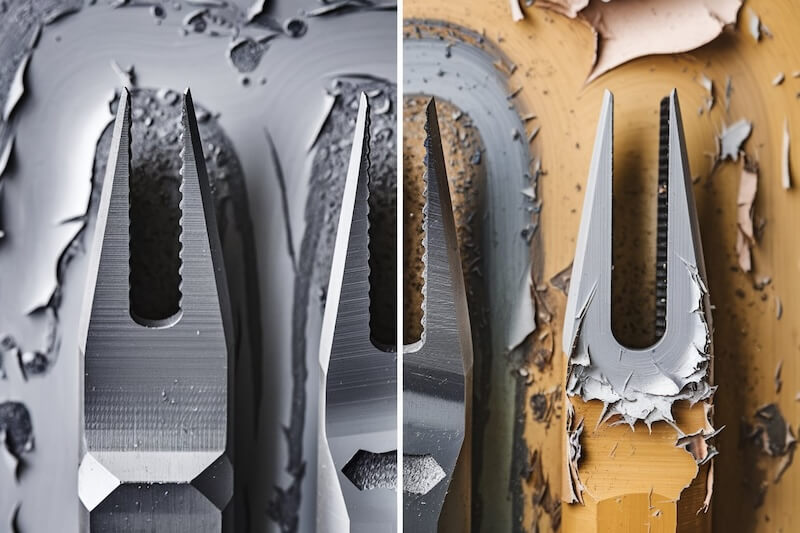

Improved Quality and Surface Finishes

Tools that stay sharper for longer produce higher-quality parts, reducing rework, rejects, and customer complaints.

Details:

- Razor-Sharp Edges: Consistently sharp cutting edges deliver tighter tolerances and improved dimensional accuracy.

- Superior Surface Finish: Carbide tools minimize burrs and other surface defects, enhancing the functional and aesthetic aspects of housing components.

- Fewer Defects: Stable tool performance results in more uniform products, boosting overall reputation and customer satisfaction.

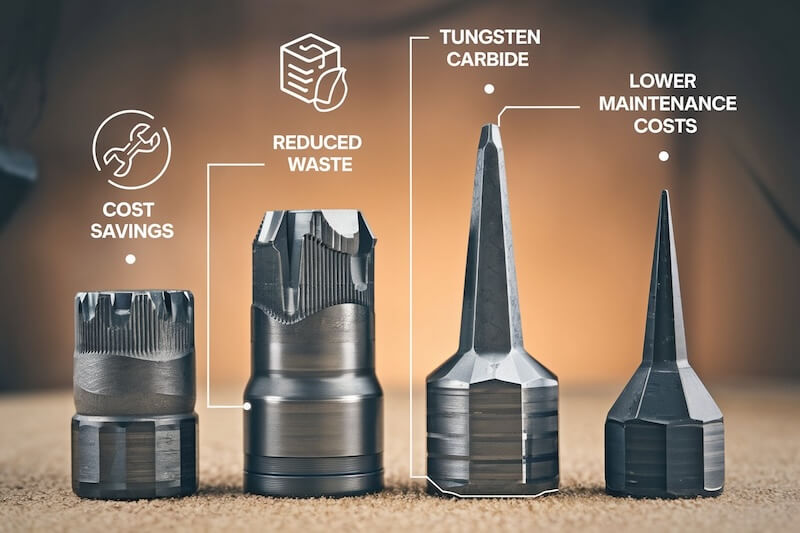

Cost Savings Over the Tool’s Lifecycle

While carbide tools may require a slightly higher initial investment, their durability and efficiency yield significant cost advantages over time.

Details:

- Longer Tool Life: Carbide tools can outlast traditional steels multiple times over, reducing inventory costs and waste.

- Lower Maintenance Expenses: Less frequent sharpening and fewer emergency replacements mean lower maintenance labor and consumables.

- Better Return on Investment: Improved productivity and reduced scrap rates ensure that the initial expense pays off through operational savings.

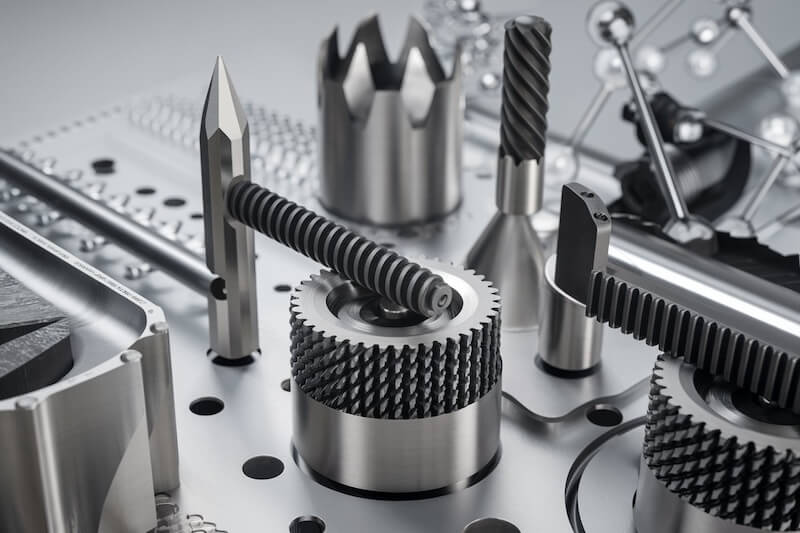

Versatility and Adaptability Across Applications

Tungsten carbide’s performance benefits apply to a wide range of housing types, from automotive casings to precision enclosures for electronics and beyond.

Details:

- Material Flexibility: Carbide tools handle a variety of materials—from standard alloys to exotic metals—without performance drop-offs.

- Scalability: Whether running small batches or large-scale production, carbide’s consistent performance supports ongoing operational growth.

- Future-Ready: As housing designs evolve and become more intricate, carbide tooling remains adaptable, ensuring readiness for new challenges.

Partnering with a Reliable Carbide Tool Supplier

Working with an experienced supplier ensures you get the right grade of carbide and the optimal tool geometry to meet your specific housing cutting needs.

Details:

- Expert Consultation: Knowledgeable providers help select carbide grades and coatings tailored to your materials and production parameters.

- Customization: Specialized tool shapes and edge treatments further boost performance, extending tool life and product quality.

- Long-Term Support: With reliable after-sales service, regrinding options, and technical assistance, a strong supplier relationship maximizes your investment in carbide tooling.

Conclusion

Tungsten carbide isn’t just another material choice—it’s a strategic asset for housing cutting tool manufacturers looking to raise their game.

From improved durability and machining efficiency to top-tier surface finishes and long-term cost savings, carbide delivers tangible advantages that alternative materials simply can’t match.

By understanding its properties, comparing it to conventional options, and considering the operational gains it offers, you can confidently make the switch to tungsten carbide and secure a competitive edge in the housing tooling market.

Quick and easy: Enter your specifications and get a quote in one business day