Tungsten Carbide Extrusion Tooling

Retop specifically targeted at both machine operators and decision-makers in the extrusion punches and extrusion dies manufacturing industry. By examining the core benefits of tungsten carbide tooling—and emphasizing Retop’s capability to deliver tailored solutions—we aims to demonstrate the transformative advantages of investing in high-quality tungsten carbide tools.

Quick and easy: Enter your specifications and get a quote in one business day

Table of Contents

Expertise in Tungsten Carbide Extrusion Tooling

Retop Carbide has an excellent reputation of manufacturing the finest extrusion tooling such as extrusion punches and extrusion dies for various applications and environments in multiple industries.

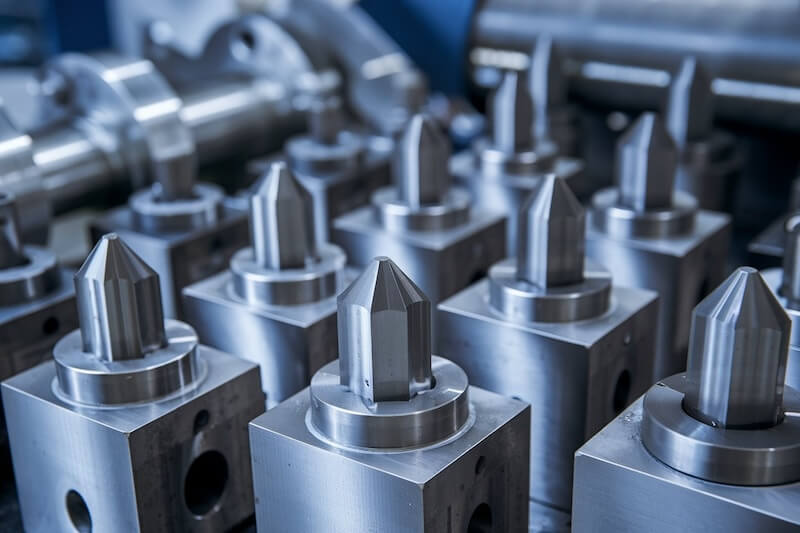

Types of Tungsten Carbide Extrusion Tooling

- Extrusion Dies

- Extrusion Punches

- Carbide Dies

- Carbide Punches

- Ceramic Dies

- Carbide Plugs

- Carbide Mandrels

- Cupping Draw Dies

- Carbide Wire Guides

- Other

Introduction: Rising Demands in Extrusion Punches and Dies Manufacturing

As manufacturers push for greater efficiency, precision, and durability, traditional materials often fall short. Tungsten carbide tooling emerges as the solution to meet increasing industry standards.

Details:

- Complex Requirements: From automotive parts to aerospace components, extrusion processes require exacting tolerances and consistent quality.

- Growing Competition: With intensified market demands, companies need advanced tooling that delivers a competitive edge.

Extending Tool Life and Reducing Downtime

Longer-lasting tools made from tungsten carbide minimize disruptions and cut maintenance costs, leading to higher overall productivity.

Details:

- Fewer Tool Changes: Durable carbide tools require less frequent replacement, reducing production halts and manual interventions.

- Predictable Maintenance Schedules: Extended tool life makes it easier to plan maintenance and avoid costly, unplanned stoppages.

The Core Properties and Advantages of Tungsten Carbide

Tungsten carbide’s exceptional hardness, wear resistance, and thermal stability make it ideal for the harsh conditions in extrusion punch and die manufacturing.

Hardness and Strength

Far more robust than conventional tool steels, tungsten carbide maintains its shape and cutting edges under extreme pressures.

Thermal Stability

Tungsten carbide tools withstand high-temperature conditions without losing integrity, ensuring stable extrusion operations.

Minimal Deformation

Consistent tool geometry leads to improved dimensional accuracy in finished parts.

Quick and easy: Enter your specifications and get a quote in one business day

Achieving Consistent, High-Quality Extrusions

Tungsten carbide tooling ensures uniform material flow and stable extrusion profiles, resulting in flawless components.

Details:

- Precision in Shape and Size: Consistent tool geometry results in parts that closely match the required specifications.

- Improved Surface Finish: Smooth, even surfaces reduce post-processing steps and enhance the performance and aesthetics of finished products.

- Lower Defect Rates: With stable tool performance, manufacturers experience fewer defective parts, ultimately increasing yield and profitability.

Boosting Productivity and Throughput

High-performance tungsten carbide tools enable faster extrusion rates and improved cycle times without compromising quality.

Details:

- Increased Production Speed: Faster forming operations and higher press tonnages are achievable with tungsten carbide’s resilient cutting edges.

- Enhanced Process Control: Predictable tool behavior allows operators to fine-tune parameters, optimizing cycle times and elevating overall efficiency.

Cost Savings and Long-Term Return on Investment

Although tungsten carbide may have a higher initial cost, it generates substantial long-term savings by reducing downtime, scrap, and frequent tool replacements.

Details:

- Reduced Scrap Material: Enhanced precision means fewer flawed parts that must be discarded, lowering material costs.

- Lower Maintenance and Replacement Costs: Tungsten carbide tools last longer, minimizing ongoing expenses and improving cost-effectiveness over time.

- Increased Profit Margins: By balancing upfront investments against operational savings and improved output quality, companies can achieve a compelling return on investment.

Versatility Across Diverse Extrusion Applications

Tungsten carbide tooling adapts seamlessly to various metals and alloys, opening opportunities for manufacturers to expand their product range.

Details:

- Compatibility with Challenging Materials: From aluminum and steel to high-strength alloys, tungsten carbide tools handle diverse extrusion tasks effortlessly.

- Future-Ready Production: As market demands evolve, having versatile tooling ensures the agility to adapt production lines quickly without sacrificing quality.

Partnering with Retop: Expert Guidance and Customized Solutions

Working with a reputable supplier like Retop provides access to expert engineering support and custom-tailored tungsten carbide tooling solutions.

Details:

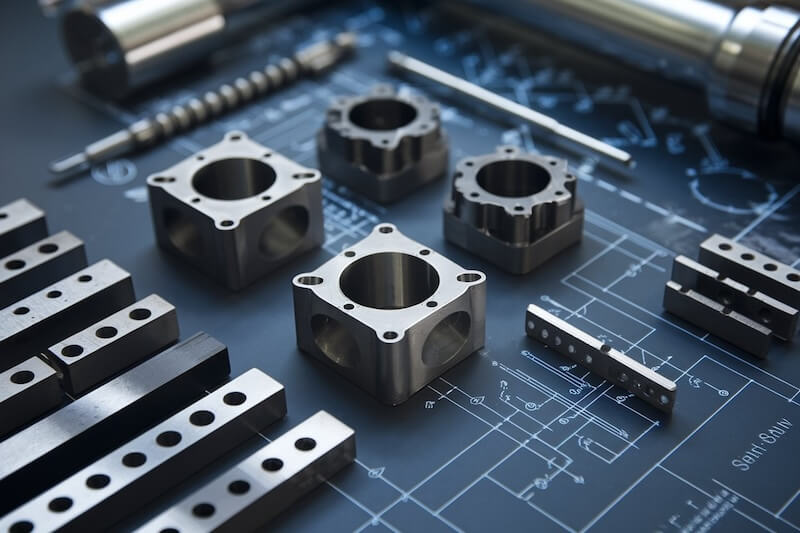

- Technical Expertise: Retop’s professionals can recommend specific carbide grades, tool geometries, and surface treatments that match unique manufacturing requirements.

- Customized Tool Design: From standard dies to complex, specialized punches, Retop can develop tools that perfectly fit production demands.

- Reliable After-Sales Service: Ongoing support, quick response times, and reconditioning services ensure that companies maintain peak operational efficiency.

Conclusion

In the demanding world of extrusion punches and dies manufacturing, tungsten carbide tooling stands as a strategic investment that drives performance, quality, and profitability.

By offering longer tool life, consistent precision, and the ability to handle challenging materials, tungsten carbide tools elevate the entire production process.

Partnering with a knowledgeable and experienced supplier like Retop ensures that manufacturers not only benefit from superior tooling but also gain access to the expertise, customization, and support needed to maintain a competitive advantage in a rapidly evolving market.

Quick and easy: Enter your specifications and get a quote in one business day