Tungsten Carbide Knives

We will structure into eight key point designed to help knife tool manufacturers understand the comprehensive benefits of tungsten carbide knives. The goal is to instill confidence that tungsten carbide knives are not only a superior choice in cutting applications but also present a range of options—from standard shapes to specialized geometries—offered by Retop. By exploring these advantages and product varieties, you can make informed decisions that drive better results and profitability in their manufacturing processes.

Quick and easy: Enter your specifications and get a quote in one business day

Table of Contents

Expertise in Tungsten Carbide Knives

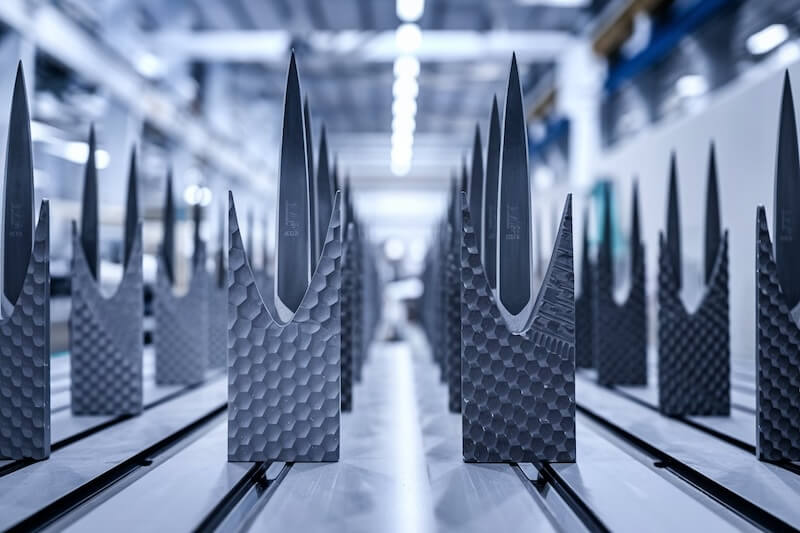

Retop Carbide’ world class slitting knives, shearing knives, chopping knives and rotary and stationary tungsten carbide knives will meet your specifications and exceed your expectations.

Types of Tungsten Carbide Knives

- Tungsten Carbide Knives

- Carbide Knives

- Circular Knives

- Slitting Knives

- Shear Knives

- Shear Blades

- Chopping Knives

- Rotary Knives

- Stationary Knives

- Other Tungsten Carbide Knives

Introduction: The Growing Demand for Precision Cutting Tools

In a global manufacturing environment that demands tighter tolerances, greater efficiency, and longer tool life, traditional cutting materials often fall short. Tungsten carbide knives have emerged as the go-to solution, addressing these heightened expectations.

Details:

- Evolving Industry Standards: From electronics and packaging to automotive and aerospace, precision cutting requirements are escalating.

- Rising Performance Expectations: Manufacturers and end-users alike seek tools that deliver exceptional accuracy, stability, and throughput gains.

Why Tungsten Carbide? Understanding the Material’s Core Properties

Tungsten carbide’s unique metallurgical structure endows it with significant performance advantages compared to traditional steels and even some advanced ceramics.

Details:

- Exceptional Hardness: Tungsten carbide retains sharp, wear-resistant cutting edges far longer than standard high-speed steel.

- High Density and Rigidity: Its stability under stress ensures dimensional accuracy and minimal deformation during challenging cuts.

- Thermal Conductivity: Controlled heat dissipation helps maintain cutting integrity and reduces distortion caused by elevated temperatures.

Advantages Over Conventional Knife Materials

Tungsten carbide knives outperform conventional materials, offering measurable improvements in production quality, efficiency, and durability.

Extended Tool Life

Carbide’s durability reduces the frequency of blade changes, lowering downtime and labor costs.

Higher Cutting Speeds

Capable of maintaining edge integrity at higher speeds, tungsten carbide knives increase throughput and productivity.

Consistent Surface Finish

Stable, long-lasting edges produce smoother cuts and fewer defects, enhancing overall product quality.

Quick and easy: Enter your specifications and get a quote in one business day

Improved Cost-Effectiveness and Operational Efficiency

While tungsten carbide knives may represent a higher initial investment, their long-term benefits far outweigh short-term expenses.

Details:

- Lower Maintenance and Replacement Costs: Prolonged edge retention translates to fewer tool changes, less sharpening, and reduced inventory management complexity.

- Predictable Performance: With reliable wear patterns, managers can plan maintenance more accurately, improving workflow and minimizing unexpected downtime.

- Better Return on Investment: Enhanced productivity, reduced scrap rates, and improved product consistency lead to tangible cost savings over the knife’s life cycle.

Types of Tungsten Carbide Knives for Diverse Applications

Not all cutting applications are identical. Retop’s range of tungsten carbide knives ensures that manufacturers can find precisely the right tool for their specific requirements.

Details:

- Straight-Edge Knives: Ideal for precision slicing of films, foils, and thin sheets, ensuring minimal distortion and clean, uniform cuts.

- Circular Blades: Perfect for rotary cutting applications, such as slitting or trimming processes, delivering consistent results at high speeds.

- Profiled and Custom Geometry Knives: Tailored shapes, serrated edges, or unique angles meet specialized cutting challenges in industries like packaging, electronics, or food processing.

- Multi-Edged and Indexable Inserts: Allow for quick tool changes and prolonged tool life, maximizing efficiency for high-volume production lines.

Enhancing End-Product Quality and Market Competitiveness

The switch to tungsten carbide knives isn’t just about internal efficiencies; it directly impacts the final product and, consequently, market positioning.

Details:

- Tighter Tolerances and Uniformity: Consistent, high-quality cuts result in improved assembly times, less material waste, and a superior finished product.

- Improved Customer Satisfaction: By investing in top-tier cutting tools, manufacturers can guarantee that end-users receive components and products that meet exact specifications.

- Strengthened Brand Reputation: Reliability and excellence in product output strengthen a manufacturer’s reputation, fostering long-term client relationships and opportunities for market expansion.

Sustainability Benefits through Longer Tool Life and Reduced Waste

Modern manufacturing considers not just performance and cost, but also environmental impact. Tungsten carbide knives contribute to greener operations.

Details:

- Less Frequent Disposal: Extended tool life means fewer worn blades end up in landfills, contributing to a more sustainable tool management cycle.

- Energy Savings: Efficient cutting operations can reduce energy consumption by minimizing rework, waste, and the need for energy-intensive secondary processes.

- Compliance with Environmental Standards: As regulations tighten, using durable, long-lasting tools can align with sustainability targets and corporate responsibility goals.

Partnering with Retop: Expert Guidance, Quality Products, and Ongoing Support

Selecting the right tungsten carbide knives is easier with a knowledgeable partner like Retop, who offers not just the tools, but the expertise to use them optimally.

Details:

- Technical Consultation: Retop’s experts assist in choosing grades, geometries, and edge treatments that align with unique cutting conditions.

- Customization and Prototyping: Whether standard shapes or custom-engineered solutions, Retop can modify designs to suit specific industry challenges.

- After-Sales Service and Reconditioning: Ongoing support, quick regrinding, and tool maintenance services ensure that manufacturers get maximum ROI and performance longevity.

Conclusion

Tungsten carbide knives represent a strategic upgrade for cutting tool manufacturers seeking reliable performance, enhanced product quality, and long-term cost savings.

Their unique material advantages, coupled with the ability to customize blades for a wide range of applications, position tungsten carbide knives as the premium choice for cutting solutions.

With a trusted partner like Retop, industry decision-makers can confidently invest in tungsten carbide knives—expanding their tool arsenal and driving better outcomes in accuracy, efficiency, and sustainability.

Quick and easy: Enter your specifications and get a quote in one business day