Metallography is a scientific method used to study the microstructure of metals and alloys, and it plays a vital role in the development, quality assurance, and failure analysis of tungsten carbide tools. In the field of cemented carbides, metallography provides essential insight into grain size, phase distribution, porosity, and binder integrity—all of which directly affect the performance and reliability of carbide tools.

What Is Metallography?

Metallography is the study of the structure and properties of metals and alloys using microscopic examination techniques. It involves a series of preparation steps—cutting, mounting, grinding, polishing, and etching—followed by observation under optical or electron microscopes.

For cemented carbides like tungsten carbide (WC) bonded with cobalt (Co), metallography reveals the internal architecture of the material, which is often invisible to the naked eye but critical for ensuring quality.

Why Metallography Matters in Tungsten Carbide Tool Production

1. Microstructure Analysis

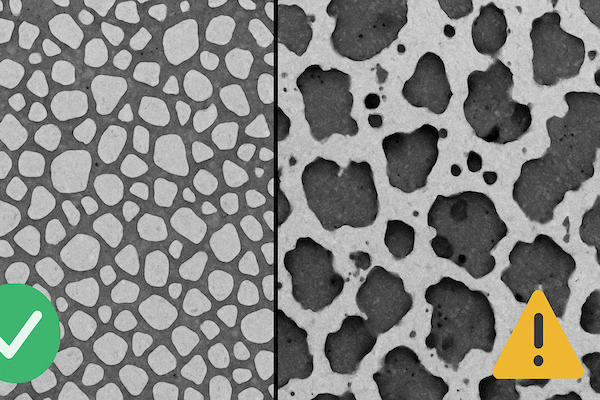

Tungsten carbide is a composite material made of hard WC particles and a ductile cobalt binder. Metallography helps visualize:

WC grain size and shape

Cobalt (binder) phase distribution

Grain boundary phases and secondary carbides

Porosity and defects

Each of these features influences tool hardness, toughness, and wear resistance.

2. Quality Control

Metallographic inspection ensures that:

The grain size is within specification (e.g., submicron, ultrafine)

The binder is evenly distributed and free of pores

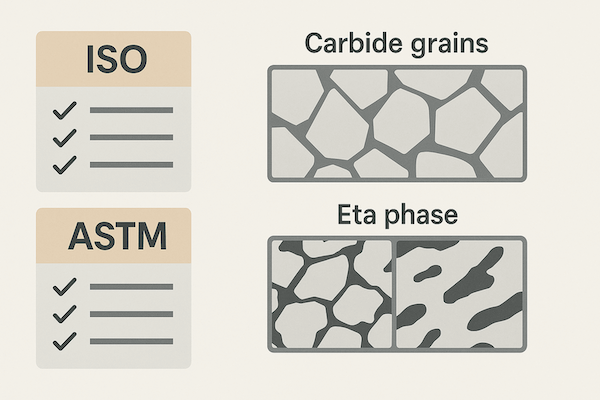

There are no abnormal phases like graphite, eta phase (η), or free tungsten

This guarantees consistency and prevents tool failure during demanding applications like machining, mining, or oil & gas drilling.

3. Failure Investigation

When carbide tools fail prematurely, metallography is used to determine root causes such as:

Binder depletion

Thermal fatigue

Micro-cracking

Phase transformation under heat

Corrective actions can then be taken in manufacturing or usage conditions.

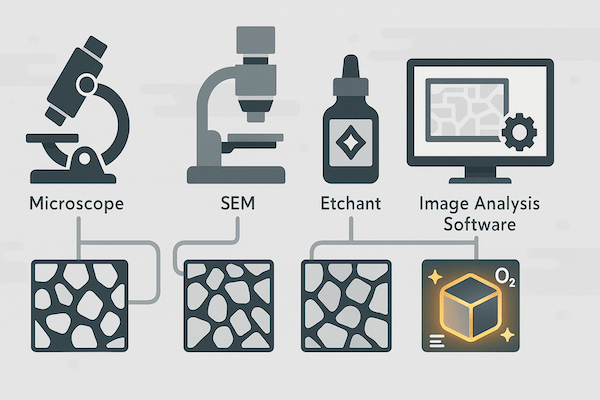

Key Metallographic Techniques for Carbide Tools

| Technique | Purpose |

|---|---|

| Optical Microscopy | Grain size, porosity, binder assessment |

| Scanning Electron Microscopy (SEM) | High-resolution imaging of micro-cracks, phase boundaries |

| Etching (Murakami’s Reagent, etc.) | Reveals WC grain boundaries and cobalt pools |

| Image Analysis Software | Quantifies phase content, grain distribution |

These techniques help establish and maintain stringent quality standards in tungsten carbide manufacturing.

Standards and Classification

Organizations such as ISO and ASTM provide standardized metallographic methods for cemented carbides:

ASTM B657 – Guide for metallographic preparation of WC-Co

ISO 4499 – Image analysis and classification of structure

These ensure global consistency in quality assessment.

Conclusion

Metallography is an indispensable tool in the world of tungsten carbide. It allows manufacturers to control microstructure, improve tool life, and reduce production errors. Whether for R&D, process optimization, or failure diagnosis, metallography bridges the gap between material science and real-world tool performance. As carbide tools continue to be used in harsher environments, metallography will remain central to innovation and quality control.