Quality Assurance

We ask you to follow the below six parts to reassure you about the quality assurance measures in place at Retop Carbide manufactuering facility. And we believe that only high-quality quality assurance can make our company more stable and long-term operation.

Strictly in Tungsten Carbide Quality Standard

Retop Carbide is committed to providing the highest-quality products and services through our advanced inspection, equipment and our documented Quality Assurance Program.

Quality Assurance Program

- State-of-the-Art Production Equipment and Facilities

- Strict Raw Material Selection and Supplier Vetting

- Rigorous Quality Control and Inspection Processes

- Compliance with International Certifications and Standards

- Transparent Communication and Documentation for Overseas Buyers

- Responsive Customer Service, After-Sales Support, and Continuous Improvement

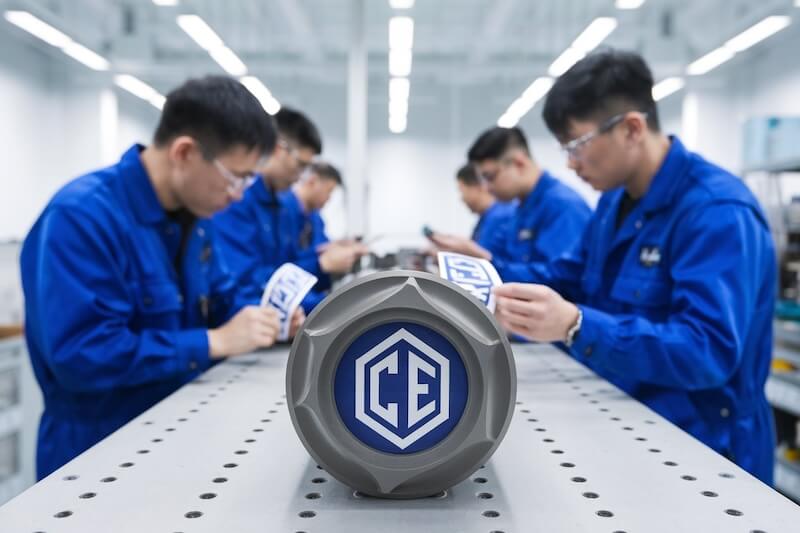

State-of-the-Art Production Equipment and Facilities

Utilizing advanced CNC machines, automated pressing, in-house tooling, precision grinding, and dedicated R&D to ensure superior tungsten carbide quality.

Advanced CNC Machines

Precision Control: Use high-precision CNC machinery to accurately shape tungsten carbide components, ensuring tight tolerances.

Consistent Quality: Automated machining processes minimize human error, producing uniform products across large batches.

Automated Pressing and Sintering Units

Stable Material Density: Automated pressing ensures even material distribution, reducing internal stress and potential flaws.

Controlled Heating Cycles: Advanced sintering furnaces maintain precise temperatures, achieving ideal hardness and structural integrity.

In-House Tooling and Mold-Making

Customized Solutions: On-site mold-making capabilities allow tailored designs for specific client requirements.

Quality Control at Source: By producing molds in-house, the company directly controls every aspect of product formation.

Cutting-Edge Grinding and Polishing Machines

Surface Excellence: High-speed grinders and polishers deliver smooth finishes, enhancing wear resistance and performance.

Consistent Dimensions: Automated finishing ensures dimensional accuracy, meeting stringent international standards.

Dedicated Research and Development Labs

Continuous Improvement: In-house R&D teams test new techniques, materials, and coatings, staying ahead of industry trends.

Faster Innovation Cycles: Direct innovation results in quicker adaptation to client needs and market changes.

Strict Raw Material Selection and Supplier Vetting

Sourcing from certified suppliers, performing rigorous inspections, enforcing quality agreements, and ensuring safety compliance for top-grade raw materials.

Certified Raw Material Suppliers

Retop Carbide sources raw materials exclusively from certified suppliers, ensuring the purity and quality of tungsten carbide and binders used in our products. This strict selection process guarantees that the foundational materials meet international quality standards, providing a reliable basis for high-performance tooling.

Incoming Material Inspection

Every batch of raw materials undergoes rigorous inspection, including chemical composition analysis and physical property verification. This thorough assessment ensures that only the highest quality materials proceed to production, eliminating defects and maintaining consistency in the final products.

Quality Agreements with Suppliers

We establish comprehensive quality agreements with our suppliers, outlining specific quality criteria and expectations. These agreements ensure that our suppliers adhere to stringent standards, fostering a reliable supply chain that consistently delivers high-grade materials essential for top-tier tungsten carbide tooling.

Safety and Compliance Checks

Retop Carbide enforces strict safety and compliance checks for all raw materials, ensuring that our production processes align with international environmental and safety regulations. This commitment not only protects our workforce and environment but also reassures overseas buyers of our dedication to responsible manufacturing practices.

Rigorous Quality Control and Inspection Processes

Implementing in-process checks, advanced testing, non-destructive inspections, and comprehensive final audits to maintain consistent product excellence.

Raw material testing

Ensuring the highest quality raw materials is foundational to producing superior tungsten carbide products. Comprehensive raw material testing involves verifying chemical composition, assessing physical properties, and confirming supplier certifications. By rigorously testing incoming materials, Retop Carbide eliminates impurities and inconsistencies at the source, guaranteeing the reliability and performance of the final products.

In-Process Checks at Every Stage

Continuous quality checks during each production stage—pressing, sintering, machining, and finishing—ensure that any deviations are detected and corrected immediately. This proactive approach maintains the integrity and performance of tungsten carbide parts throughout the manufacturing process.

Advanced Testing Techniques

Retop Carbide employs advanced testing methods, such as hardness testing and metallographic analysis, to evaluate the microstructure and mechanical properties of our products. These sophisticated techniques verify that each part meets the required specifications for durability and performance, providing assurance of quality to our clients.

Non-Destructive Testing

Implementing non-destructive testing (NDT) methods, such as ultrasonic inspection and magnetic particle testing, allows us to identify internal and surface defects without compromising the integrity of the components. NDT ensures that our tungsten carbide products are free from hidden flaws, guaranteeing reliability and safety for end-users.

Dimensional Inspection

Precise dimensional inspection is the final verification step before completing quality audits. Retop Carbide conducts meticulous dimensional checks to ensure that each part meets exact specifications required by customers. Utilizing advanced measuring tools and techniques, these inspections confirm that the parts have maintained their geometry and dimensional integrity throughout the manufacturing process, ensuring perfect fitment and performance in their intended applications.

Final Quality Audits

Comprehensive final audits review every aspect of the finished product against predefined quality standards. This last line of defense ensures that only the highest quality tungsten carbide parts are shipped to our overseas buyers, maintaining our reputation for excellence and reliability.

Compliance with International Certifications and Standards

Adhering to ISO 9001, CE marking, and ensuring material traceability to meet global quality and environmental standards.

ISO 9001 Quality Management System

Retop Carbide’s ISO 9001 certification demonstrates our commitment to maintaining a robust quality management system. This internationally recognized standard assures buyers that our processes are optimized for quality control, continuous improvement, and customer satisfaction.

CE Marking (When Applicable)

For products requiring CE marking, Retop Carbide ensures compliance with all relevant EU directives. This certification facilitates easier market entry for our products in Europe, providing overseas buyers with confidence in their safety and regulatory compliance.

Material Traceability and Lot Identification

Retop Carbide implements rigorous traceability and lot identification systems, allowing each product to be traced back to its raw material batch and production process. This transparency enhances accountability and enables quick resolution of any quality issues, building trust with overseas buyers.

Transparent Communication and Documentation for Overseas Buyers

Offering dedicated account managers, comprehensive after-sales support, regular feedback collection, and fostering long-term partnerships for ongoing quality assurance.

Detailed Technical Datasheets

Providing comprehensive technical datasheets that include material properties, performance specifications, and application guidelines helps overseas buyers understand the capabilities and suitability of our tungsten carbide products for their specific needs.

Inspection and Test Reports

Retop Carbide supplies thorough inspection and test reports with each shipment, offering clear evidence of quality and compliance. These documents include measurements, test results, and certifications, ensuring buyers have all necessary information to verify product quality upon receipt.

Customized Quality Control Plans

We work closely with our buyers to develop customized quality control plans that address their unique requirements and standards. This tailored approach ensures that our tungsten carbide products meet or exceed the specific quality expectations of each client.

Virtual Factory Tours and Video Demonstrations

Offering virtual factory tours and video demonstrations allows overseas buyers to witness our production processes, equipment, and quality control measures firsthand. This transparency builds trust and confidence in our ability to deliver high-quality tungsten carbide products.

Responsive Customer Service, After-Sales Support, and Continuous Improvement

Sourcing from certified suppliers, performing rigorous inspections, enforcing quality agreements, and ensuring safety compliance for top-grade raw materials.

Dedicated Account Managers

Each overseas buyer is assigned a dedicated account manager who serves as a single point of contact for all inquiries, orders, and support needs. This personalized service ensures that clients receive prompt and attentive assistance, fostering strong, long-term relationships.

Comprehensive After-Sales Support

Retop Carbide offers extensive after-sales support, including troubleshooting, maintenance advice, and tool reconditioning services. This support maximizes the performance and lifespan of our tungsten carbide products, ensuring customer satisfaction and repeat business.

Regular Feedback Collection

We actively seek feedback from our overseas buyers to understand their experiences and identify areas for improvement. This continuous feedback loop drives our ongoing quality enhancements and ensures that our products consistently meet the evolving needs of our clients.

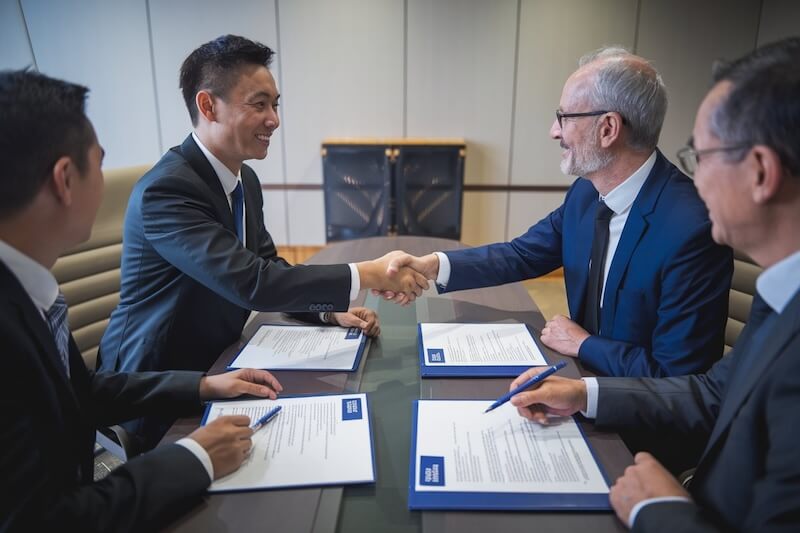

Long-Term Partnerships and Strategic Alliances

Retop Carbide aims to build long-term partnerships with our overseas buyers, offering not just products but also strategic support and collaboration. By working closely with clients, we help them achieve their quality and production goals, reinforcing mutual success and growth.

Conclusion

By implementing these six comprehensive quality assurance strategies—state-of-the-art equipment, strict raw material selection, rigorous quality control, international certifications, transparent communication, and responsive after-sales support—Retop Carbide ensures that overseas buyers receive tungsten carbide products of the highest quality.

These measures not only uphold our reputation for excellence but also provide our international partners with the confidence and reliability they need to succeed in their respective markets.

Choosing Retop Carbide means investing in a trusted partner committed to delivering superior tungsten carbide solutions that drive operational success and foster long-term business relationships.