Tungsten Carbide Saw Blade

- Material: High quality hard alloy

- Density: 14.5-14.8 g/cm3

- Hardness: HRA91 -92.5

- Features: Durable, long working life

Description:

Tungsten carbide saw blade is solid cemented carbide, the hardness of solid carbide saw blades is higher than high speed steel blade under high temperature, and carbide saw blade is more durable.

These kinds of carbide saw blades are specially manufactured for cutting off and slotting metal materials such as plain steel, chilled steel, aluminum and copper as well as difficult-to-machine materials such as stainless steel, titanium alloys and so on. Widely used in automobiles, diesel engines, motorcycles, aerospace, home appliances, instrument precision machinery and other industries.

Usually, we use coarse particle for fast cutting of thick materials or metals, and medium particle for thin object.

Advantages:

1. Top quality material, cutting accurately and grinding repeatedly.

2. Suitable for sawing plastic steel and the processing line of wood industry.

3. Quality:USA and European market approved quality.

4. OEM: Special Cutters Customized acceptable.

Specifications:

| Name: | Tungsten carbide saw blade |

| Other names: | Tungsten carbide cutting wheel, tungsten carbide circular blade, TCT circular saw blade |

| Features | Excellent performance, non-magnetic property can be achieved. |

| Applications: | Used in automobiles, diesel engines, motorcycles, aerospace, home appliances, instrument precision machinery and other industries

|

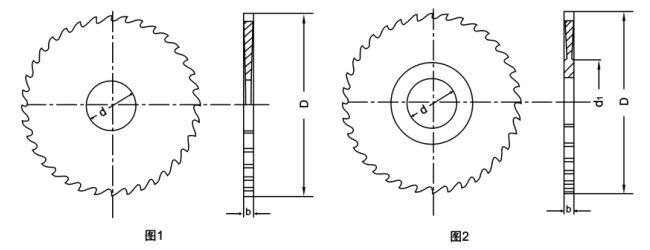

Solid carbide flat teeth saw blade:

Range of Outer diameter 12≤ D≤ 125, tolerance of thickness ±0.003; Accept OEM

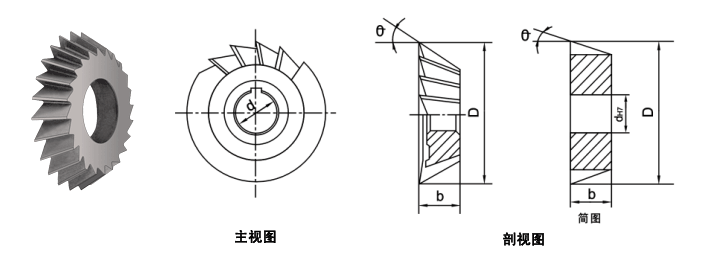

Solid carbide single angle milling cutters:

This type of cutter has a θ≥30° b≥2

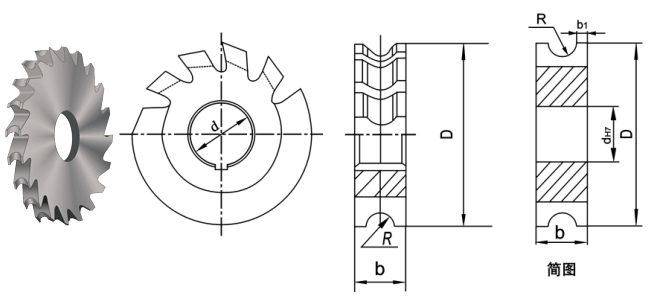

Solid carbide half-round concave milling cutters:

This type of cutter has a b≥4 b1≥1 R≥1

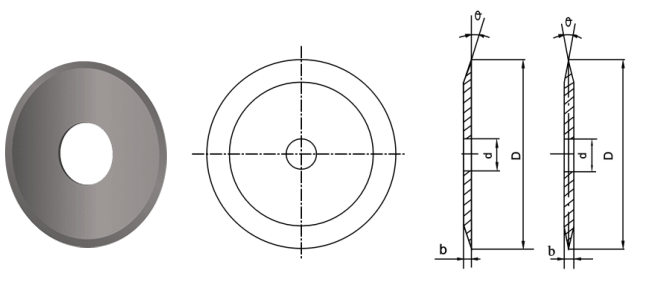

Solid carbide circular cutter: